- Drive improvement in manufacturing productivity through continuous monitoring and analysis of data

- View Production Data (Real-time, from anywhere)

- Analyze (Trends, Defect reasons, Efficiency Metrics over a period of time)

- Drive processes to improve productivity and quality

- ANDON is a manufacturing term referring to a system to notify management, maintenance, and other workers of a quality or process problem.

- The centrepiece is a signboard incorporating signal lights to indicate which workstation has the problem

PMS - Key Features

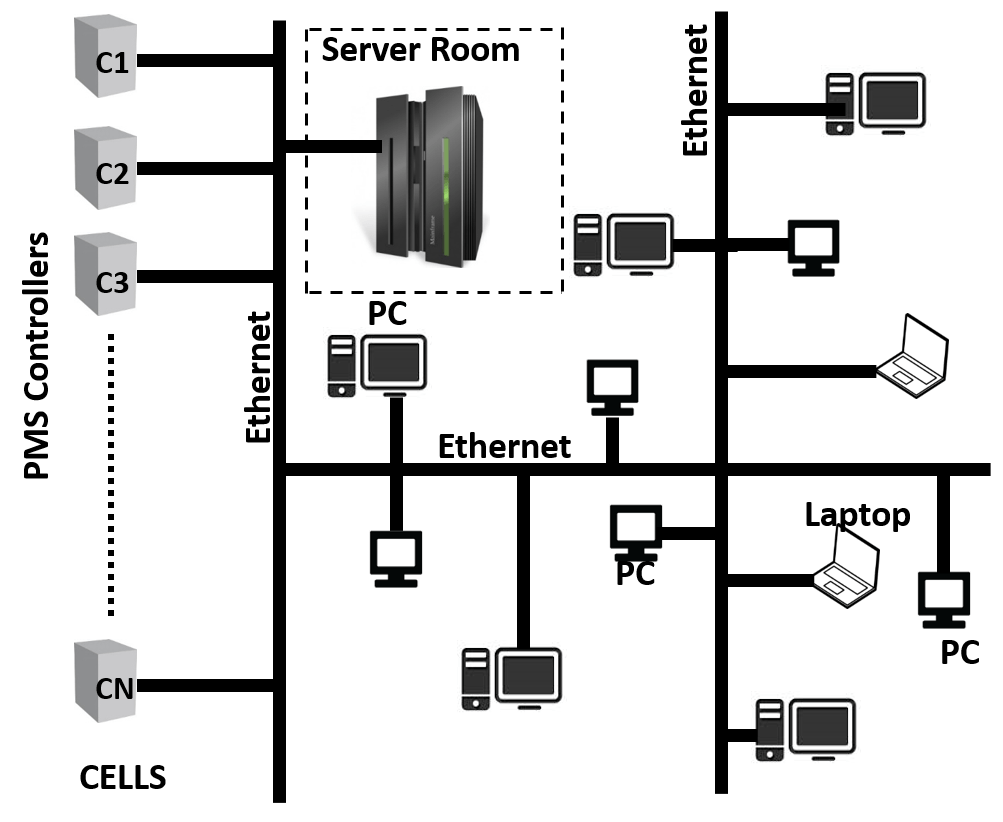

- PMS System Components

- PMS Hardware (Controller, Sensors, Displays, Keyboards)

- PMS Software (PMS Server Application, PMS Client Application)

- PMS Controllers can be configured as cluster of networked devices for plant wide monitoring & control of production

- PMS Key Features

- Single controller for two cells. Any 24V PNP Sensor can be connected to the controllers. An RS485 display, RS232 Keyboard for each cell.

- Simulate and Configure each cell independently.

- Server and Client Applications to configure, control and monitor operations real-time

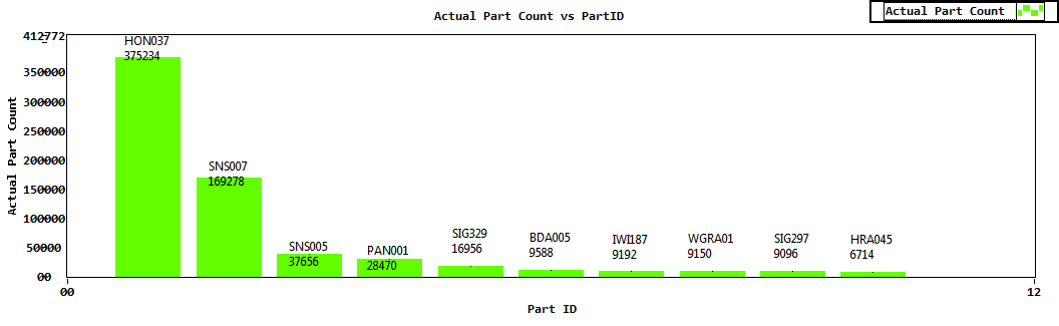

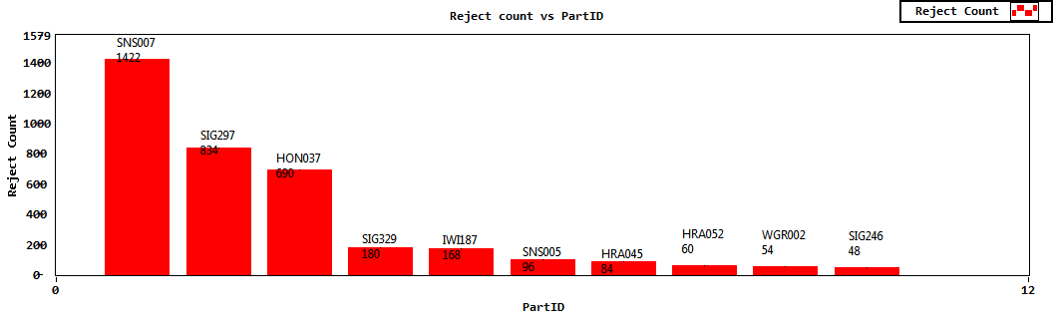

- Display Target & Actual Counts, Efficiency & OEE metrics, logging of Downtime and Defect reasons

- Built-in Data mining/analytics to review Job trends, job quality and operations data

- Log operators, Compute operations data, Generate customized reports and consolidated shift reports

- The PMS system can be customized to meet your requirements

PMS - Architecture

- Server-Client Architecture with ability to configure the system and track metrics from anywhere on the customer network.

- C1, C2, .. CN are PMS controllers connected to the Ethernet (company network)

- PMS server application runs on a server

- PMS Client application runs on any desktop PC or laptop connected to Ethernet (Company network)

PMS - Software

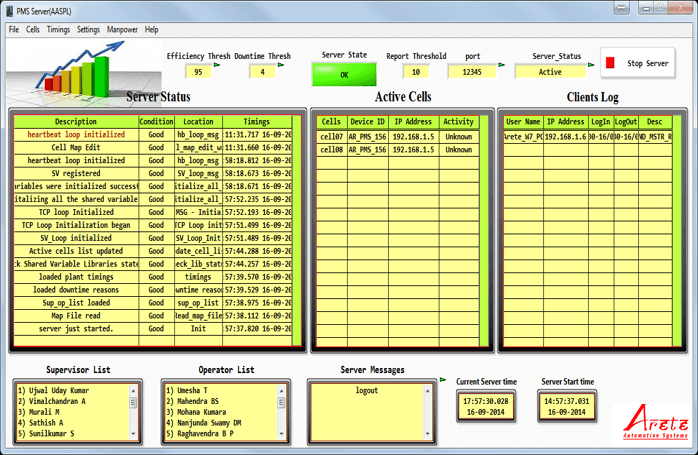

PMS Server Application

- Server Application is meant for configuring the system – adding controllers, supervisor and operator id’s and passwords, downtime reasons, paths for data logging etc.

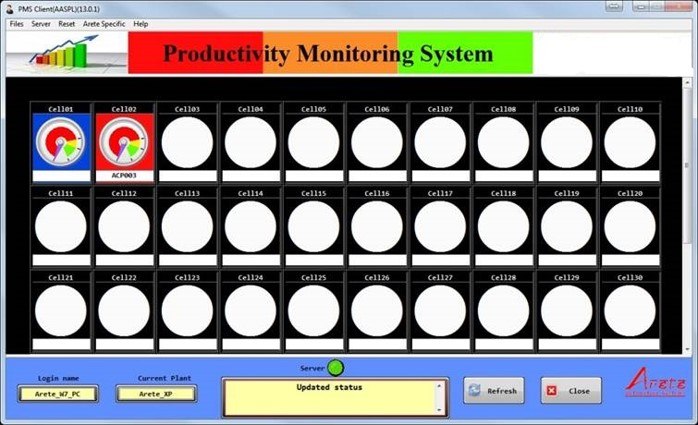

PMS Client Application

- Client Application is meant for job setup, control and/or real-time monitoring of cells/machines on the factory floor.

- Client application can be launched from any PC/laptop connected to the company network

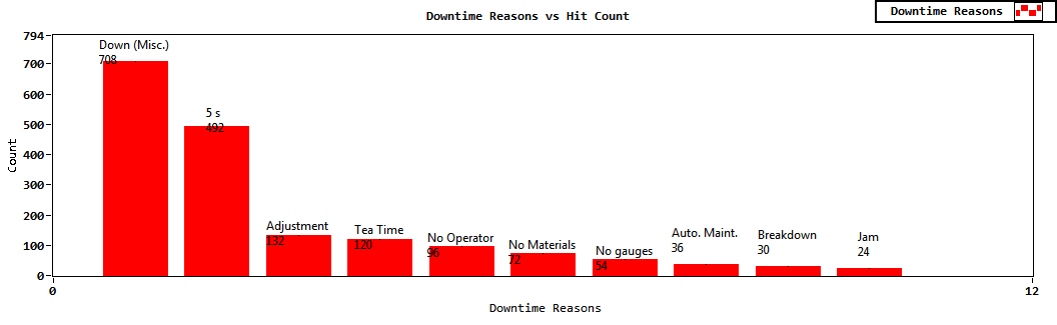

PMS – Analytics (Can be customized)

- Graphs, Trends, Detailed text reports are made available

- Graphs and Reports can be customized as per your requirements.