- Ar-i8000+ (MSWIM) Indicator is a state of the art, scalable, intelligent, accurate and high-speed real-time system that interfaces to load-cells banks to extract axle weight, speed & spacing information of axles passing over the weigh-bridge.

- Ar-i8000+ used by our OEM customers is approved for MSWIM applications (up to 60 KMPH) by Govt. Of India.

- Indicator capable of interfacing with load-cell based sensors as well as bending plate sensors.

- The indicator is designed to seamlessly plug-in to the next higher level application software (Toll Management software)

- Additional customization to cater to a specific need is possible due to its scalable and reconfigurable hardware and software architecture.

- Designed in India

Key Features (MSWIM)

- Integrated 400MHz Freescale Industrial -real-time controller with Xilinx Spartan-6 FPGA, 128 MB DRAM for high-speed and inline signal processing.

- Wind River VxWorks real-time operating system (RTOS) for extreme reliability and determinism.

- Galvanic isolation of measurement front end for better accuracy & improved reliability. Inbuilt secondary protection against lightning.

- Supports 4/6 Wire load cell connections. 5V DC excitation for 4 load cells (350Ω−700Ω).

- Very Low Noise, high speed 24 bit, ΣΔ ADC with integrated PGA.

- On board EMI filters for reduced interference from pick-up noise.

- 16X2 LCD display for status & weight

- Interfaces :

- 10/100BASE-TX Ethernet port with built-in FTP and HTTP servers for system update & configuration.

- RS-232 DTE Serial Port with arbitrary baud rate support for peripheral devices.

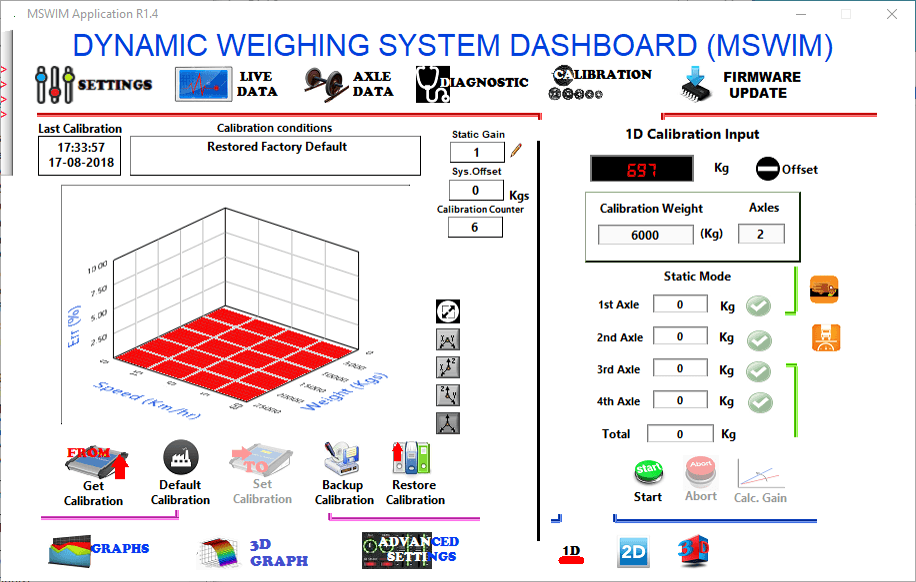

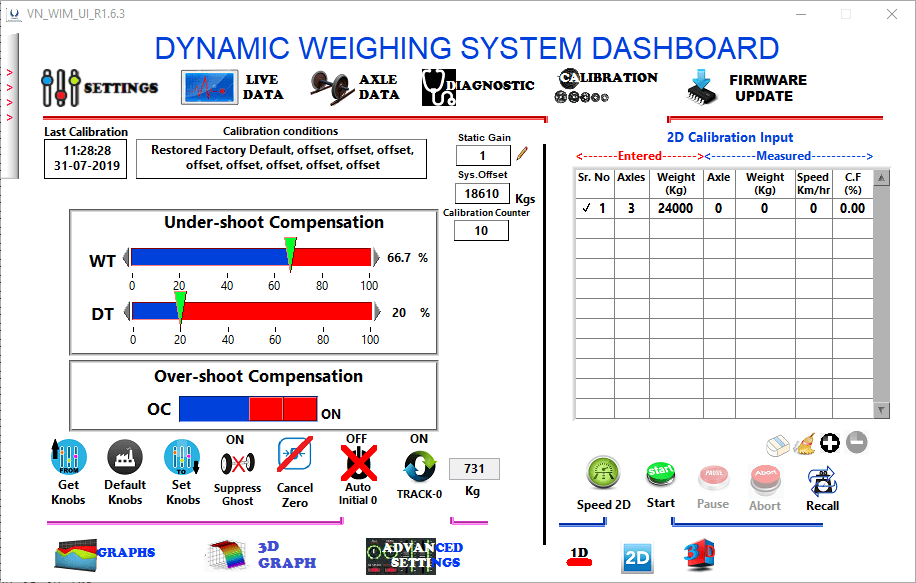

- Password protected multi-dimensional calibration for variation due to load cell and vehicle dynamics.

- OTP for calibration.

- Integrated vehicle separator and anti-rollback functionality.

- RTC and on-board SD card for data logging.

- Field Firmware upgrade features for easily updates.

- Auto-Diagnostics of Load cells & other critical system components.

- Windows Application (user interface) s/w for configuration, calibration, debug & data analysis.

Measurement Accuracy

- Static

- Weight: ±0.5%.

- Repeatability: ±0.1%

- Dynamic

Speed (KMPH) |

Weight Accuracy |

Axle Speed |

Axle Spacing |

Repeatability |

|

|---|---|---|---|---|---|

| MSWIM | <= 60 | +/- 5% | +/- 5% | +/- 5% | +/- 2% |

Load Cell

- Configuration: 4/6 wire

- Excitation: 5V DC for 4 loads cells of 350 ohm to 700 ohm

- Sensitivity: 1/2/3 mV/V

- Galvanic Isolation: 1000V RMS for 1min

Bending Plates

- Excitation: 5V DC

- 2 Plates per Lane

- Sensitivity: From 0.50 mV/V.

- Galvanic Isolation: 1000V RMS for 1min.

Ethernet

- Communication rate: 10 Mb/s, 100 Mb/s auto-negotiated

- Maximum cabling distance: 100 m/segment

- Compatibility: IEEE 802.3

RS232

- Maximum Baud rate- 230,400 bps

- Maximum cabling distance: 5m

Power

- Supply Voltage : 12V DC

- Consumption: 15W